PG Diploma in Piping Design Engineering by Udemy

Learn Piping Design Engineering

Course Highlights

- Learn the core concepts of Piping Designing.

- Learn the designing procedure of different Plants.

- Learns Codes & Standards used in industry

- Learn about static & Rotary Piping Equipment.

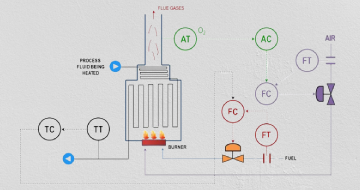

- Learn to read PFD UFD & P&ID.

- Learn about pipe fitting, components & Valves.

- Learn selection of valves & fittings

- Types of stresses in piping system & testing

- Piping Fabrication Methods

- Learn to make Isometric Drawings

- Learn to make General Arrangement Drawings

- Learn ablout all Documents involved in Designing

- Learn designing calculations like pipe size, line size calculations

- Learn different types of Supports & selection methods

- Learn 3D Piping designing in PDMS

Curriculum

2 Topics

Introduction

Course Syllabus

28 Topics

0.0 Module Introduction

1.1 Piping System

1.2 Plants Type-1

1.2 Plants Type-2

1.2 Plants Type-3

1.2 Plants Type-4

1.2 Plants Type-5

1.3 Plant Designing Type

1.4 Phases of Plant Desinging

1.5 Types of Design Companies

1.6 Knowledge Requirement

1.7 Piping & Other Departments

1.8 Codes and Standards

1.9 Piping Components

1.10 Pipe

1.11 Pipe Designation

1.12 Pipe Manufacturing

1.13 Pipe Fittings-1

1.13 Pipe Fittings-2

1.13 Pipe Fittings-3

1.14 Pipe Flanges-1

1.14 Pipe Flanges-2

1.13 Pipe Fittings-4

1.14 Pipe Flanges-3

1.15 Flange Gaskets

1.16 Valves

1.17 Valves Types-1

1.17 Valves Types-2

21 Topics

Module Intro

0.0 Equipments

1.1 Static Equipment

1.2 Tanks

1.3 Heat Exchangers

1.4 Heater & Boilers-1

1.4 Heater & Boilers-2

1.5 Columns

1.6 Reactors

1.7 Separators

1.8 Strainers

1.9 Air Vents

1.10 PIG Launchers

2.1 Rotary Equipments

2.2 Pumps

2.3 Compressor

2.4 Agitator

2.5 Turbines

2.6 Turbo Expanders

2.7 Engines

2.8 Fans & Blowers

20 Topics

0.0 Module Intro

1.1 Project Documentation

1.2 Chemical Process Selection

1.3 Anatomy of a Chemical Process

1.4 Material Balance

1.5 Energy Balance

2.1 Plot Planning

2.2 Equipment Layout

3.1 Symbols

3.2 PFD & UFD

3.3 P&ID Excercise-1 (Tank)

3.4 P&ID Excercise-2 (Heat Excanger)

3.5 P&ID Excercise-3 (Separator)

3.6 P&ID Excercise-4 (Column)

3.7 P&ID Excercise-5 (Complex)

4.0 Section Intro(ga iso dwgLinelist)

4.1 Ga dwg Ex-1(Part-1)

4.1 Ga dwg Ex-1(Part-2)

4.1 Iso dwg Ex-1

4.1 Line-List

14 Topics

0.0 Module Intro

1.1 Fluid & Its Properties

1.2 Types of Fluids

1.3 Fluid at Rest

1.4 Fluid in Motion

1.5 Continuity Equation

1.6 Bernoulli's Thoerem-1

1.6 Bernoulli's Thoerem-2

1.7 Pipe Size Calculation

1.8 Pipe Thickness Calculation

1.9 Pump Selection

1.10 Insulation Thickness Calculation

1.11 Mitre Bend Calculation

1.12 Dyke Wall Calculations

12 Topics

0.0 Module Intro

1.1 Fabrication Activities

1.2 Types of Welding

1.3 Piping Lining

1.4 Piping Insulation

2.1 Supports Introduction

2.2 Types of supports

2.3 Hanger Suppoerts

2.4 Clamp Supports

2.5 Strap Supports

2.6 Saddle Supports

2.7 Slide Supports

11 Topics

0.0 Module Introduction

1.1 Types of Stresses

1.2 Static Loads

1.3 Dynamic Loads

2.1 Visual Inspection

2.2 Liquid Penetration Test

2.3 Magnetic Particle Test

2.4 Radiographic Testing

2.5 Ultra-Sonic Testing

2.6 Hydrstatic Pressure Testing

2.7 Pneumatic Pressure Testing

PG Diploma in Piping Design Engineering