IIRF Online > Business > Industry > Piping > Know Read Understand Piping & Instrumentation Diagrams P&IDs

Know Read Understand Piping & Instrumentation Diagrams P&IDs by Udemy

Learn how Process Control, Safety Instrumented Systems, Interlock & Alarms are represented in engineering P&ID drawings

Course Highlights

- Understand and evaluate the purpose, content, and importance of P&IDs to the construction, commissionning, safe operation and maintenance of a process plant

- Learn how to read, interpret and successfully understand ALL P&IDs through numerous real industrial examples

- Identify the 5 key sections of your P&ID (title block, grid system, revision block, notes and legend, engineering drawing block)

- Know and identify valve symbols on your P&IDs (gate, globe, ball, butterfly, needle…)

- Know and identify valve actuator symbols on your P&IDs (pneumatic, hydraulic, electric, single acting spring return, double acting…)

- Know the standards and conventions for valve status (open, closed, throttled)

- Identify valve position and failure mode on your P&IDs (LO, LC, FO, FC, FAI…)

- Know and identify process equipment symbols on your P&IDs (pumps, compressors, heat exchangers, columns, furnaces, reactors, vessels, containers, mixers…)

- Know and identify piping symbols on your P&IDs (process, pneumatic, electric, hydraulic…)

- Determine specific information about a process piping including type of material in the line, line size, line number and type of insulation when applicable

- Know and identify pipe fitting symbols on your P&IDs (flanges, reductions, caps, spool pieces, unions…)

- Know and identify the P&ID symbols of safety devices that are used to safely isolate, vent & drain process equipment for ease of maintenance (spectacle and spade blinds, double block and bleed valves…)

- Know and identify pneumatic, electric, hydraulic and instrument signal lines on your P&IDs

- Know and identify instrumentation symbols on your P&IDs (flow meters, temperature transmitters, pressure gauges…)

- Know and identify the location of instruments, recorders, modifiers and controllers on your P&IDs (field mounted, board mounted, inaccessible…)

- Know the lettering and numbering standards based on ISA symbolgy for piping, instruments and equipment designation on your P&IDs

- Trace the flow of a process stream into your P&ID, through the pipes and equipment, and out of the P&ID

- Understand the importance of process control and how it is displayed on your P&IDs

- Successfully interpret basic process control schemes on your P&IDs

- Understand the different process control options and how they are displayed on your P&IDs (cascade control, split range control, ratio control, batch control, selective control…)

- Define the term Flow Control and explain how it is displayed on your P&IDs

- Define the term Temperature Control and explain how it is displayed on your P&IDs

- Define the term Pressure Control and explain how it is displayed on your P&IDs

- Define the term Level Control and explain how it is displayed on your P&IDs

- Understand the control of pressure in a pipe and explain how it is displayed on your P&IDs

- Understand the control of flow in a pipe and explain how it is displayed on your P&IDs

- Understand flow merging control and explain how it is displayed on your P&IDs

- Understand flow splitting control and explain how it is displayed on your P&IDs

- Understand centrifugal pump control systems (discharge throttling, variable speed drive, minimum flow…) and explain how they are displayed on your P&IDs

- Understand positive displacement pump control systems (recirculation pipe, variable speed drive, stroke adjustment…) and explain how they are displayed on your P&IDs

- Understand compressor control systems (capacity control, variable speed drive, anti-surge…) and explain how they are displayed on your P&IDs

- Understand heat exchanger control systems (direct control, bypass control, back pressure control…) and explain how they are displayed on your P&IDs

- Understand reactor temperature control systems and explain how they are displayed on your P&IDs

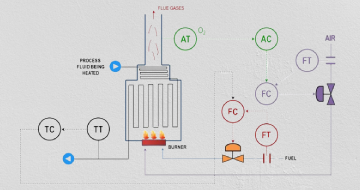

- Understand fired heater control systems and explain how they are displayed on your P&IDs

- Understand container and vessel control systems and explain how they are displayed on your P&IDs

- Understand electric motor control systems (ON / OFF actions) and explain how they are displayed on your P&IDs

- Know and understand the concept of Safety Instrumented Systems (SIS) and explain how safety instrumented functions are displayed on your P&IDs

- Know and understand the concept of Alarm Systems and explain how alarms are displayed on your P&IDs

- Identify safe operating limits based on system designs as displayed on your P&IDs

- Know and understand how Fire and Gas Detection Systems (FGS) are displayed on P&IDs

- Assess emergency situations and regulatory compliance issues using your P&IDs

Curriculum

1 Topic

Introduction

1 Topic

Before you start this course

4 Topics

What's a P&ID ?

Why is a P&ID so important ?

Who uses P&ID's ?

How do P&ID's look like ?

9 Topics

Learning objectives

Introduction

Anatomy of a P&ID

The title block

The drawing scale

The grid system

The revision block

Changes

Notes and legends

15 Topics

Learning objectives

Valve symbols

Valve actuator symbols

Control valve designations

Standards and conventions for valve status

Process equipment symbols

Piping symbols

Pipe fitting symbols

Isolating venting & draining symbols for ease of maintenance

Instrumentation

Sensing devices and detectors

Location symbols

Modifiers and transmitters

Indicators and recorders

Controllers

3 Topics

Example #1 : Identifying process equipment and flow paths on a P&ID

Example #2 : Identifying valve position and failure mode on a P&ID

Example #3 : Identifying the symbols on a P&ID

5 Topics

Learning objectives

Piping designation code

Equipment designation code

Instrument designation code

Miscellaneous designation codes

1 Topic

Important notes

3 Topics

Learning objectives

The process

Process control

3 Topics

Learning objectives

The control loop

Process control terms

15 Topics

Learning objectives

Single control loops : Feedback control

Pressure control loops

Flow control loops

Level control loops

Temperature control loops

Multi-variable loops

Multi-variable loops : Feedforward control

Feedforward + Feedback

Cascade control

Split range control

Operations on control signals

Ratio control

Batch control

Selective control

30 Topics

Learning objectives

Why do we need to control ?

How to control ?

Pipe control 1/4

Pipe control 2/4

Pipe control 3/4

Pipe control 4/4

Flow control 1/2

Flow control 2/2

Pump control 1/7

Pump control 2/7

Pump control 3/7

Pump control 4/7

Pump control 5/7

Pump control 6/7

Pump control 7/7

Compressor control 1/3

Compressor control 2/3

Compressor control 3/3

Heat transfer equipment control 1/6

Heat transfer equipment control 2/6

Heat transfer equipment control 3/6

Heat transfer equipment control 4/6

Heat transfer equipment control 5/6

Heat transfer equipment control 6/6

Reactor temperature control

Fired heater control 1/2

Fired heater control 2/2

Container and vessel control 1/2

Container and vessel control 2/2

25 Topics

Learning objectives

Safety strategies

Concept of Safety Instrumented Systems (SIS) 1/4

Concept of Safety Instrumented Systems (SIS) 2/4

Concept of Safety Instrumented Systems (SIS) 3/4

Concept of Safety Instrumented Systems (SIS) 4/4

Anatomy of a SIS 1/8

Anatomy of a SIS 2/8

Anatomy of a SIS 3/8

Anatomy of a SIS 4/8

Anatomy of a SIS 5/8

Anatomy of a SIS 6/8

Anatomy of a SIS 7/8

Anatomy of a SIS 8/8

Showing safety instrumented functions on P&IDs

Discrete control

Concept of Alarm systems 1/5

Concept of Alarm systems 2/5

Concept of Alarm systems 3/5

Concept of Alarm systems 4/5

Concept of Alarm systems 5/5

Fire and Gas Detection Systems (FGS)

Electric motor 1/3

Electric motor 2/3

Electric motor 3/3

6 Topics

About this practice session

P&ID example #1 : Legend and specifications

P&ID example #2 : Hydrogen delivery station

P&ID example #3 : Centrifugal compressor

P&ID example #4 : Hydrogen from shale gas

P&ID example #5 : Fired heater

2 Topics

Downloadable resources

Bonus

Know Read Understand Piping & Instrumentation Diagrams P&IDs